WHICH RACKING IS RIGHT FOR YOU?

Choosing the best system should always take into account the number of products, the volume of each product, the throughput rate, physical size and weight of products, expected growth, and a number of other variables including the type of materials handling equipment to be used.

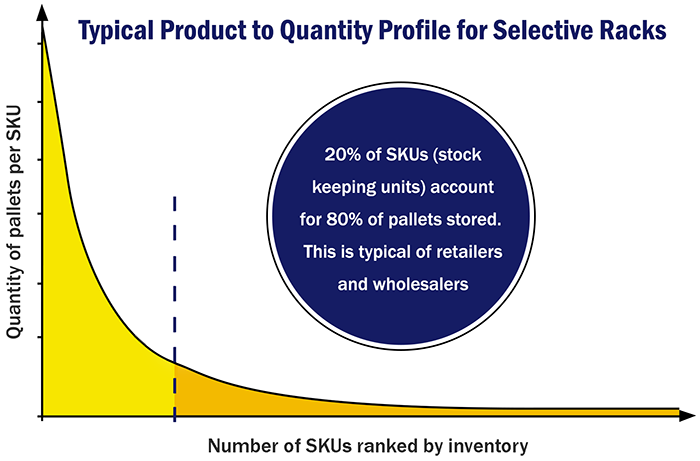

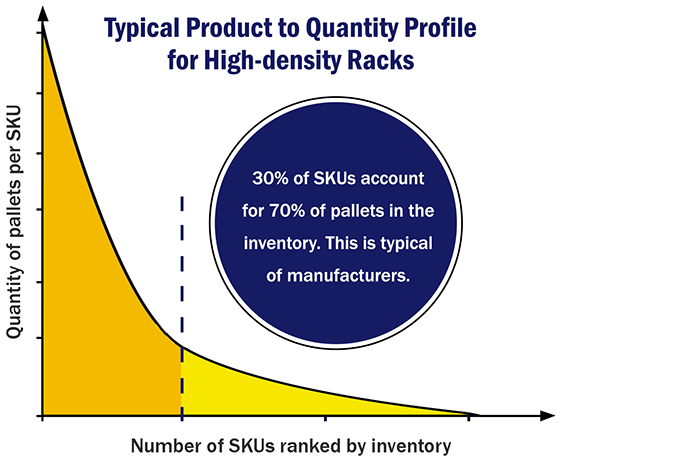

Determining your product movement profile is a good place to start. If your business holds a large number of SKUs and a small volume for each, you’ll need a Selective Pallet Racking system. The reverse and you may benefit from a High-density Racking system.

Selective Storage

Selective pallet racking systems provide immediate, ready access to virtually all pallets. This is needed where there are a high number of SKUs with only a few pallets or less of each, which is typical of most retailers and wholesalers. Read more.

High-density Storage

High-density pallet racking systems are more space efficient than Selective pallet racking systems but do restrict access to individual pallets, so are not suitable for all operations. However, where there are many pallets of each SKU, as is the case with manufacturers, high-density, non-selective solutions can provide cost savings in a range of areas. Read more